ALL PRODUCTS FAMILIES

Energy Precision Sealing Systems

Extreme Temperature Insulating Materials

Our Materials insulate and protect structures in extreme temperatures (-192°C to 1150°C). Flexible for sealing or rigid for walls construction. They demonstrate reliability for over 20 years.

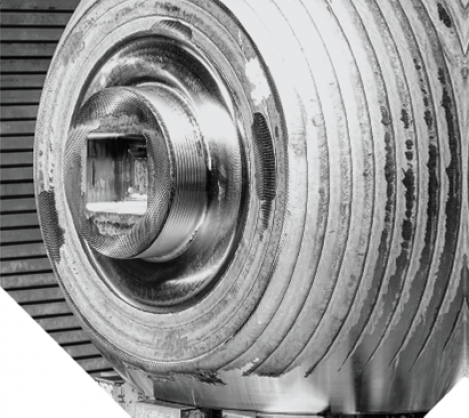

Seats, Balls and Slabs for Valves

Our Seats, Balls and Slabs ensure leak-free closing and opening of on-off valves.Offered as a complete kit "seats & balls" or "seats & slabs", they guarantee a perfect fit of the components and perfectly seal the valve.

O-Rings

Our O-Rings ensure perfect static and dynamic seals between two parts assembled radially (shafts) or axially (covers). Our O-Rings can withstand the most extreme temperatures and fit in the smallest spaces.